Membrane Switches: A Affordable Solution for Advanced Control Systems

Membrane Switches: A Affordable Solution for Advanced Control Systems

Blog Article

Membrane Switch Modern Technology: The Secret to Trusted and Affordable User Interfaces

Membrane layer switch modern technology has arised as a crucial element in the layout of user interfaces, giving both reliability and cost-effectiveness throughout a varied variety of applications. Its durable building makes sure resistance to environmental challenges, while the versatility in style enables customized remedies that meet specific sector requirements. As we explore the complex benefits of membrane layer buttons, their possibility for advancement raises inquiries concerning future applications and advancing patterns. What does the next phase hold for this modern technology in a significantly digital landscape?

Recognizing Membrane Layer Switch Modern Technology

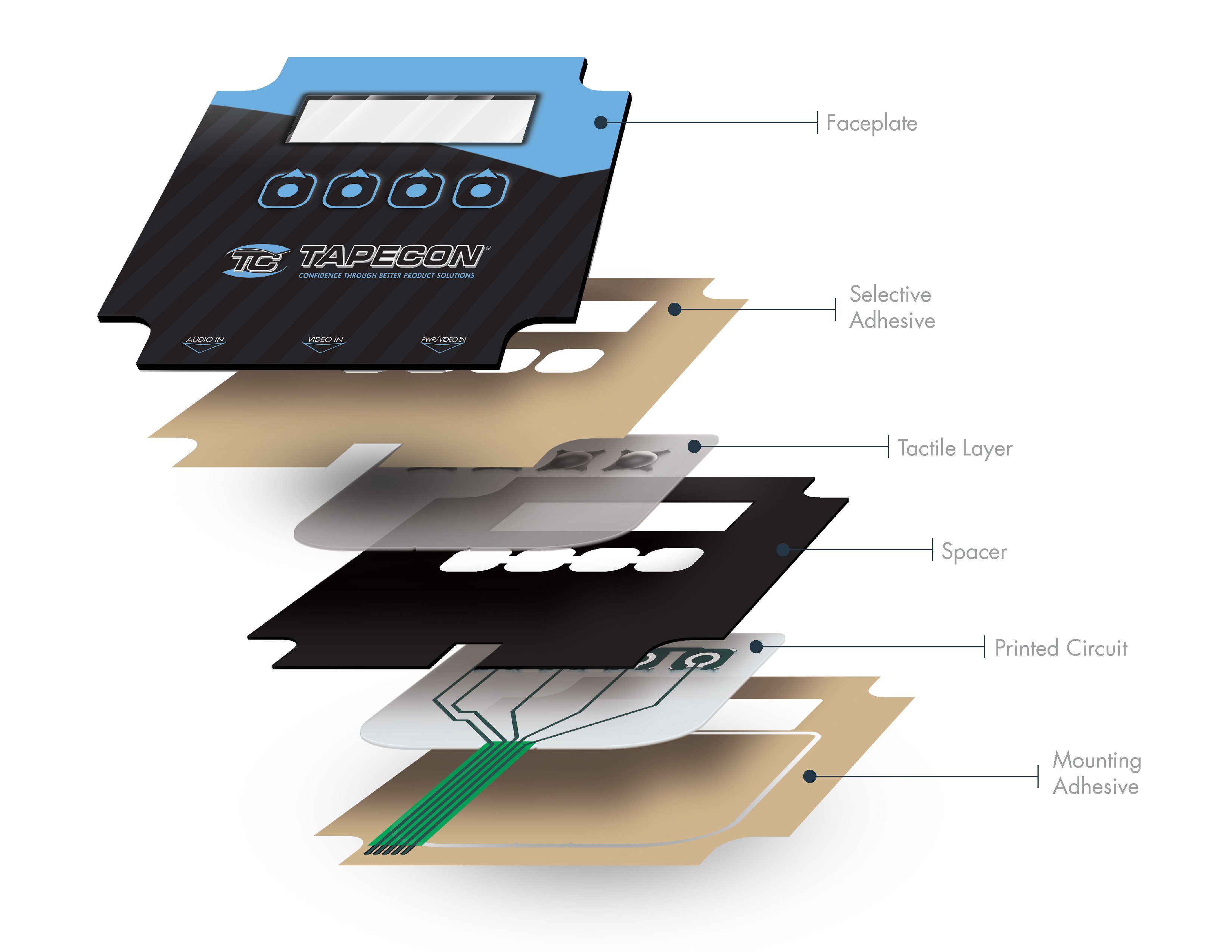

Membrane layer button technology is a widely utilized user interface service in different digital gadgets, offering a seamless blend of performance and design. This modern technology integrates numerous layers of products, generally including a visuals overlay, spacer layer, and a circuit layer. The visuals overlay presents the user interface components, while the spacer layer separates the circuit layer from the overlay up until a user triggers a switch.

When stress is put on the overlay, the circuit layer finishes the electrical circuit, sending a signal to the gadget. This mechanism enables different arrangements, including tactile responses and backlighting choices, improving individual interaction. Membrane switches are generally manufactured utilizing sturdy materials such as polyester or polycarbonate, making certain durability and resistance to environmental elements like wetness and dust.

The flexibility of membrane switches enables their application in diverse sectors, including medical gadgets, consumer electronic devices, and industrial controls. Their portable design enables combination right into space-constrained atmospheres, providing an efficient individual interface without jeopardizing aesthetic charm. Understanding the intricacies of membrane button technology is vital for suppliers and developers seeking to create trusted and effective human-machine interfaces.

Secret Advantages of Membrane Layer Buttons

While numerous user interface options exist, membrane layer changes offer distinct advantages that make them a preferred option in countless applications. One of the main benefits is their toughness; membrane layer buttons are made to hold up against extreme environmental conditions, consisting of moisture, dirt, and temperature level changes, ensuring durable efficiency. This strength significantly lowers the need for constant replacements, thereby decreasing total maintenance expenses.

In addition, membrane buttons are light-weight and compact, making them ideal for applications where room is limited. Their inconspicuous layout adds to a smooth look without jeopardizing performance.

Cost-effectiveness is likewise a significant benefit, as the production procedure for membrane changes often tends to be much less pricey compared to standard mechanical buttons. This cost, incorporated with their integrity and simplicity of installation, settings membrane layer changes as a practical option for a broad variety of sectors seeking efficient and effective interface.

Applications Throughout Different Industries

Just how do membrane buttons adapt to the diverse requirements of various sectors? Membrane button innovation is increasingly identified for its flexibility, making it suitable for a large range of applications throughout multiple fields.

In consumer electronic devices, membrane buttons offer a portable service for remotes and home appliances, boosting user experience via user-friendly design. Furthermore, the commercial industry leverages membrane layer switches for equipment control board, benefiting from their resistance to extreme environments, such as wetness and dirt.

Military and aerospace applications likewise make use of membrane switches for their integrity and ability to stand up to severe conditions, ensuring operational effectiveness in crucial circumstances. Additionally, the food and drink industry adopts these switches for automated systems, where hygiene and ease of operation are vital. Eventually, membrane layer buttons are customized to fulfill the unique demands of each industry, showing their necessary duty in modern technology interfaces

Design and Personalization Choices

In the realm of membrane button modern technology, layout and modification alternatives play a pivotal duty in boosting capability and customer communication. These switches can be tailored to meet particular operational see here now requirements and aesthetic choices, making them functional parts in different applications.

One of the primary customization alternatives is the format of the button itself, which can be developed to accommodate unique interface and ergonomic factors to consider. By changing the shape, dimension, and plan of buttons, manufacturers can develop user-friendly designs that facilitate convenience of use. Additionally, the unification of different colors and visuals overlays enables for branding and improved presence, making sure that users can promptly determine functions.

In addition, membrane switches can be crafted with different responsive comments mechanisms, such as elevated buttons or distinct clicks, to improve the customer experience. Different materials can additionally be chosen for resilience and environmental resistance, attending to elements such as dampness, temperature variations, and chemical exposure.

Inevitably, the substantial design and personalization options offered in membrane button technology encourage businesses to produce customized solutions that not just meet practical needs but likewise straighten with their branding and functional requirements.

Future Patterns in Membrane Buttons

As membrane switch innovation remains to evolve, future patterns are significantly concentrated on enhancing individual experience and incorporating innovative capabilities. One significant trend is the combination of touch-sensitive and capacitive modern technologies right into traditional membrane switches. This development enables more user-friendly interface, giving responsive responses while keeping a streamlined design.

Another emerging trend is using eco-friendly materials, driven by the growing need for lasting production techniques. Suppliers are looking for to lower their carbon impact by making use of recyclable substratums and low-impact inks, lining up with worldwide sustainability goals.

Additionally, the increase of the Web of Things (IoT) is prompting the incorporation of clever attributes right into membrane layer switches. Enhanced connectivity alternatives will certainly allow gadgets to interact with each other, allowing for smooth combination into broader systems.

Additionally, advancements in printing modern technologies, such as electronic printing, are enabling higher style flexibility and customization. This makes it possible for manufacturers to generate complex styles and dynamic shades cost-effectively.

Verdict

In final thought, membrane switch innovation my response represents a crucial innovation in individual interface layout, providing considerable benefits in resilience, personalization, and cost-effectiveness. page As innovations continue to emerge, especially in touch-sensitive user interfaces and lasting products, the potential for membrane changes to improve customer experience and capability remains promising.

Report this page